3D printing’s manufacturing applications may not include printing atoms, but even that goal isn’t unreachable. The technology had evolved significantly since the 1980s when its idea was initially conceived.

Indeed, its rapid development is not unconnected to the rapid growth of certain markets today. You probably wonder how valuable 3D printing could be to your manufacturing effort. Here are some practical applications of 3D technology for a manufacturer.

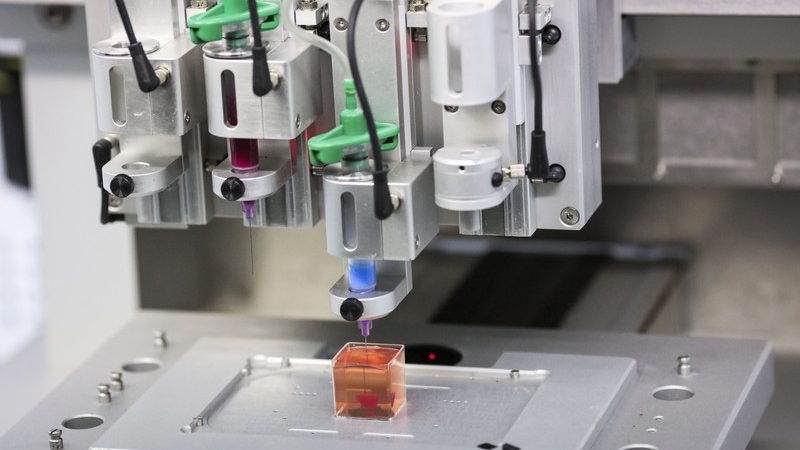

Prototyping

Before you start ordering expensive titanium and wood treatment reagent, how about prototyping with 3D technology instead? The value of 3D printing to prototyping across all industries can’t be overstated. Its proper name is “rapid prototyping.”

The name is because of how fast it makes the task of getting your idea in physical shape. You don’t need expensive working models when a 3D printed model can demonstrate your idea to investors. Rapid prototyping isn’t a new idea to the manufacturing scene; it’s already happening and becoming increasingly rapid.

Low-Demand Manufacturing

There’s no doubt that 3D printing is too slow for manufacturing large-volume products with massive demands. However, low-volume products with low demand are fair game with a 3D printer. It’s a valuable technology to test run new product lines with uncertain market demand.

You’ll find such type of fabrication mostly with high-value goods that command low demand. It satisfies the need for customization of look and function without raising the price sky-high. Technological advancements in 3D technology also mean that high-volume product fabrication may not be a pipe dream for the future.

Parts and Components

Sometimes, the crank of your power tool breaks down, and you have to wait for a week until a new one arrives. 3D printing saves you the stress of the wait and allows you to continue the job within a few minutes. Start your printer, load up the crank design, print it, replace the old crank with it, and continue your work.

3D technology simplifies the problems of industrial holdups by providing an easy alternative for replacement parts. You can quickly make valuable repairs to your tools and equipment without spending too much money. Many small-scale manufacturers also innovate fast by using the technique to reduce the development costs for their products.

It’s not just small businesses that benefit from 3D technology either because even Porsche is using it. Massive companies like Airbus can replace complex plane interior components by simply printing the exact dimensions. In 2018, Ford won major honors for its lightweight assembly lift assist that was 50% cheaper than its counterpart using FDM.

Lightweight Products

Weight is one of the great enemies of manufacturers and consumers worldwide. Replacing some heavy parts of your product with lighter 3D printed parts is a new hobby for manufacturers. With the right 3D printed casing and material components, you can make your final product extremely lightweight.

Final Thought

As 3D technology continues to evolve, its status as the future of manufacturing also continues to increase. You are certain to benefit from the capabilities of printing atoms once that evolution is complete.