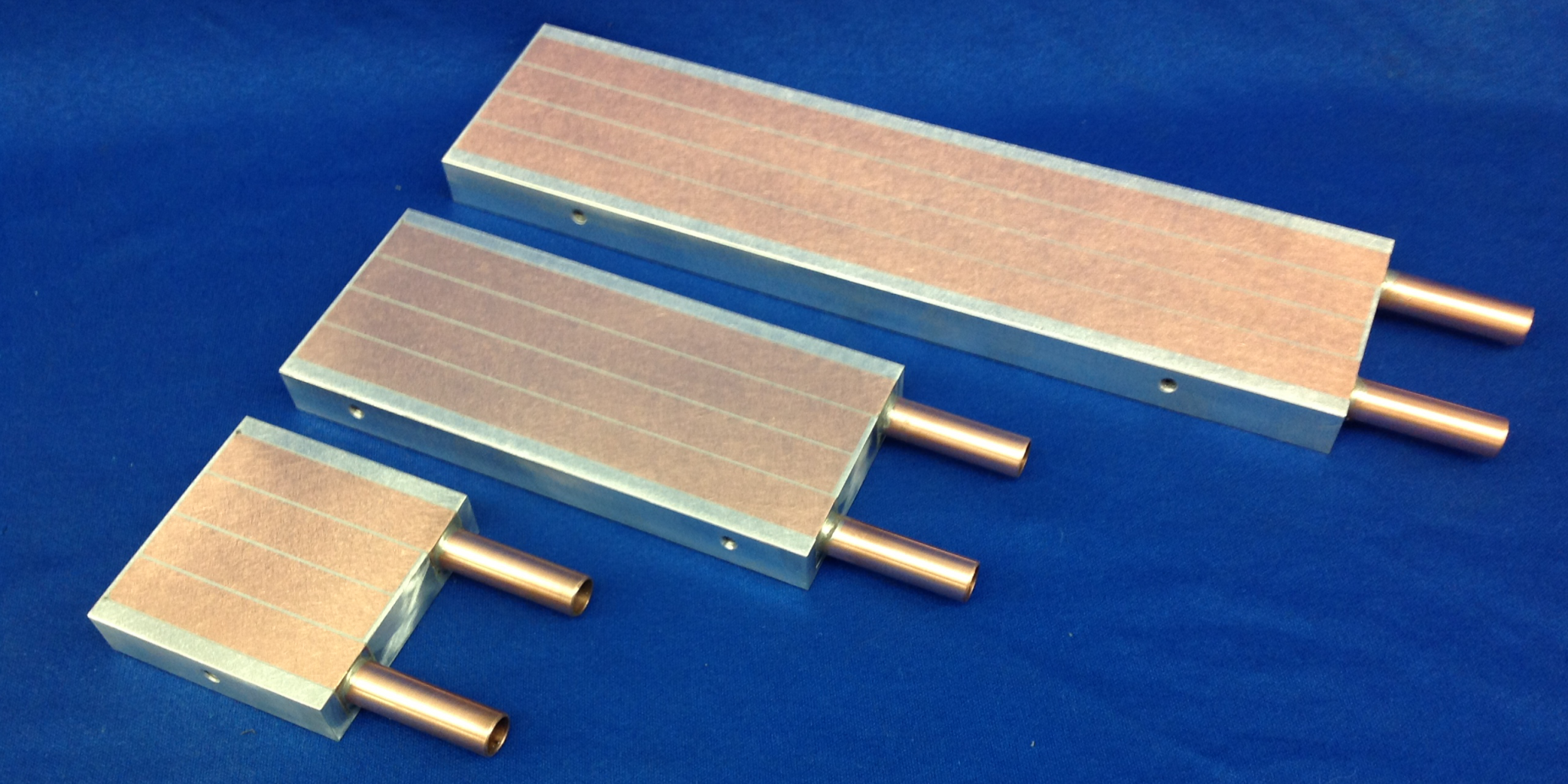

Instead of using a space-consuming heat sink and fan, you can replace it with a liquid-cooled cold plate. When a liquid cold plate needs a heat exchanger, pump, plates, and tubing, the cold plate will have enough placement options because it can use outside the airflow. In liquid cooling systems, it transfers a maximum of four times heat equal to air mass.

The latest manufacturing technologies have significantly addressed the concerns about the costs and leakage of cold plates. When it matters to the cooling system, the question looming around is what is the best liquid for receiving maximum performance.

The selection of working fluid is imperative similar to selecting hardware for liquid cold plates. Suppose you can use the correct heat transfer fluid. In that case, it can provide high heat conductivity, low freezing point, poor toxicity, heat stability, poor viscosity, compatibility with systems metal, stability of heat, etc. If you choose an improper liquid, it will have disadvantages like bad heat transfer and may end up with system failure and clogging.

Despite the improvement, we can find in the liquid cold plate designs, the options to select coolant is limited. In most situations, water can use a coolant; but water with additives and many other fluids is apt for some applications.

What Are the Best Cooling Choices?

Because of its poor freezing temperature, you cannot always use water for cooling, even though it has excellent cooling properties on a cold plate. For changing the character of the coolant, Glycol or similar additives are required to use to manage the operating environment of the cold plate.

There are fluids with low freezing temperatures than water, but their heat transfer ability is abysmal. So, the temperature range requirements are the primary consideration for cold plate fluid. Also, the selected fluid must have compatibility characteristics with the cold plate’s internal metals to resist the chances of hitting with corrosion.

What Are the Coolants used for Liquid Cooling Applications Commonly?

- Water solutions and inhibited Glycol

- Water

- Dielectric Fluids

- Deionized Water

Water Solutions and Inhibited Glycol:

The commonly used water solutions and inhibited Glycol are ethylene glycol (EGW) and water and propylene glycol and water solutions (PGW). Ethylene has a high boiling point and good thermal properties. Also, it has excellent stability over various temperature ranges, with excellent thermal conductivity and high specific heat. PGW is a food-friendly coolant. However, EGW is more desirable than PGW.

Water:

Water is highly compatible with copper, and copper is the best heat conductor. It has excellent thermal conductivity and heat capacity. Since water will have more impurity possibilities, it is imperative to use good quality water to minimize corrosion. So, it is better to use deionized water or filtered water.

Dielectric Fluid:

While working with sensitive electronic items, it is a non-conductive fluid, better than water. They are thermally stable, non-explosive, and non-flammable. It low corrosive character compared to deionized water. The dielectric fluid is costly, and thermal conductivity is low.

Deionized Water:

Deionized water is a good insulator and is hence used in electrical components. It is clean water without impurities and free of salts and minerals, which is a reason for corrosion and scaling. While using deionized water in cold plates, it is better to use stainless steel tubing.

Conclusion:

In liquid cooling applications, deionized water, dielectric fluids, water, and glycol-water solutions are the commonly used heat transfer fluids. You must select the proper heat transfer fluid suitable for the fluid path, which offers corrosion protection with the right chemistry.