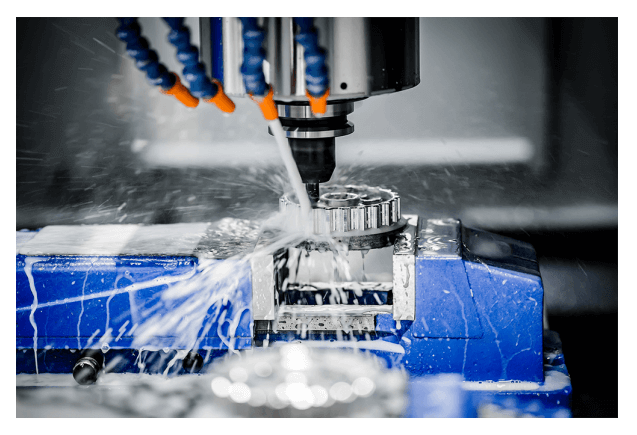

CNC machining services from China play a critical role in the creation of numerous intricate elements needed in multiple industries. Although mass production can work for different applications, other sectors need tailored parts for specific areas and use. The possibility and capability to design these parts accurately using a computer have driven several companies to seek the input of CNC machining for their success. Everything, including the medical industry and transportation, relies on these machining parts. Thanks to the development of computers, the process has a way of allowing for intricate tailored designs in production.

Types Of CNC Machines

There are several types of CNC Machines on the market. They all come in handy in the manufacturing processes. Generally, they are six. But in this blog post, we put our focus on the 3 best and leading in the sector.

- CNC Router Machine

This is one of the most common pieces of machinery you may come across in the industry, whether as a learner or devoted user. The machine is built in a way that it can precisely operate the CNC technology without the input of a human being.

Routers are used for producing slightly larger dimensions coupled with an in-built design that helps to cut wood and sheet metal. The routers are also mostly found in the 3 axes coordinate set up. This design allows the machine to cut different profiles and pocket 3-dimensional machining.

Other than that, there are CNC routers with the 4,5, and 6 axes. These ones come with an additional rotary which is used in rotating the tool located at the workpiece of the device. The machine is suitable for cutting intricate shapes.

- CNC Lathes Machine

A lathe is utilized in developing a precise yet conical part. The machine is prominent for making good use of turning centres when cutting a tool and shaving off excess elements of materials as it rotates.

- CNC Electric Discharge Machines

ED machining (EDM) comes with elements that can be used to make certain types of shapes inside a particular material by utilizing an electrical release. The material is typically dispensed from a workpiece using a progression of electrical releases from two anodes. The mentioned anodes are then isolated using a dielectric liquid. The liquid often receives a viable electric voltage.

Final Thoughts- Industries That Use CNC Machining Services

Precision is a tenet that matters in most industries, including medical, aerospace, as well as petrochemical. Component failure in the stated market can prove to be risky in life. This explains why different businesses in the sectors mentioned need the highest levels of accuracy to be successful in their endeavours. CNC machining can help achieve the required standard of precision in order to save lives.

Besides, manufacturers in different industrial sectors have CNC machines used to create needed products. The machines use various techniques to operate. Some industries can choose to use CNC machining to fulfil orders online.

That’s it from us. As a prospect business professional, you need to educate yourself with the basics of operating CNC machines, including why and where they may be needed.