Nylon is a widely used synthetic thermoplastic polymer. It is a flexible, durable, and very versatile material that is commonly used in injection molding applications. Nylon is often used as an affordable alternative for other materials such as latex, rubber, and silk.

Items made from nylon plastic (PA) tend to have features such as:

- High melting point

- Excellent tensile strength

- Resistant to abrasions and chemicals

- Low friction

Thanks to its specific chemical composition, nylon has a very high melting point. That makes it a top alternative for metal components exposed to high temperatures. The most common uses are in car engines and other machinery where there is high-friction. The fact that it doesn’t heat that easy when in a high-friction situation makes it unique. Same as other thermoplastic materials, once it reaches its melting point, it turns to liquid instead of burning. That means it can be easily melted, remolded, or even recycled.

Another great trait of nylon plastic is that it easily combines with other materials. That way, we can improve much of its qualities and make the produced items applicable to other uses.

One such example is filling it with fiberglass. That will reinforce its tensile strength on account of its flexibility that will decrease. Plus, it will make it more brittle.

Different Variants of the Nylon Material

There are different variants of nylon, but not all are popular and commonly used as Nylon 6, Nylon 66, Nylon 6/66, and Nylon 6/6.

The numbers reveal the number of carbon atoms found among the amine and the acid groups. The single digits like 6 reveal that the polymer is made from a single monomer, which is in conjunction with itself. That makes it a homopolymer. The two digits, like 66, reveal that the polymer is made from several other monomers in relation to each other. That makes them comonomers.

Then there is the slash that means the polymer consists of several groups of comonomers that are in relation to each other. The term used to describe that is a copolymer.

Nylon Plastics in Everyday Life

Thanks to its excellent versatility, nylon is used for all sorts of products, such as:

- Fishing line

- Reinforcement for rubber.

- Threads and ropes

- Clothing and fabric

- And a lot more

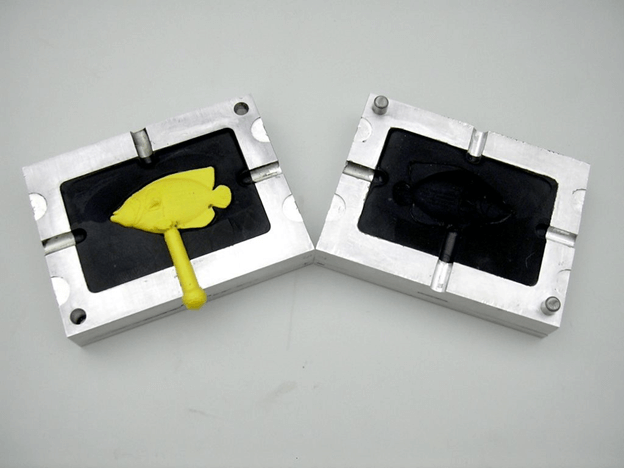

Thanks to plastic injection molding, nylon is also cast into plastic bearings, bushings, gears, and other types of mechanical equipment such as engines.

To Conclude

Nylon is no easy material to work with, especially if you are a beginner and don’t have much experience under your belt. It is a temperamental type of material, that if not treated right, can lead to low efficiencies and high scrap.

You can get consistent quality of products via injection molding by proper material handling, meticulously following all the procedures, tool design, and concentrated processing.

That’s the only path to excellent nylon molding and efficient production of excellent products. Any other approach is merely an improvisation, waste of time, money, and resources.