My be, at one time or another, you have come across metal parts with a beautiful aesthetic design and finish. Most of these parts are made from the metal aluminum because aluminum parts possess enhanced mechanical attributes. The process of anodizing aluminum entails creating a layer of oxide on the metal’s surface, a process leaves the metal surface with an exceptional finish, as well as increasing the adhesive potential of the metal. The procedure of anodizing aluminum also enables glue and specific paint primers to be easily applied to the parts, while also increasing corrosion resistance.

How anodization of aluminum is done

Even though almost all metals can be anodized, the most popular choice of metal for the process is aluminum. Anodizing aluminum involves an electrochemical process that leaves a layer of oxide film on the metal by dipping it in an electrolyte solution. In scientific terms, that aluminum is the “anode.”

The next step is to pass an electric current through the anode and the cathode. But, the best choice for the cathode is flattened aluminum bars. The current passes through the electrolyte, usually sulphuric acid, on its way between the anode and cathode.

Types of anodizing

There most famous examples of anodize include:

- Chromic Acid Anodize (CAA)

This process generates the thinnest coat of oxide on the aluminum surface. Done correctly, the chromic acid anodizing can offer protection as good as the other more advanced anodizing techniques. The result is a gray-colored surface that is capable of absorbing less color in a dye process. Aluminum parts made by this process are used in aerospace components, precision machined parts and welded assemblies.

- Boric-Sulfuric Acid Anodize (BSAA)

The BSAA offers a fantastic option to chromic acid anodize; this is mostly as a result of the rising concern over human safety/ health concerns, environmental safety concerns, and lastly, the associated costs of CAA. The BSAA process is mainly applied for the sake of paint adhesion and corrosion protection. Aluminum parts that are treated using the Boric-Sulfuric Acid Anodize process are used in precision machined components, as a paint base, and in aerospace components.

- Sulfuric Acid Anodize (SAA)

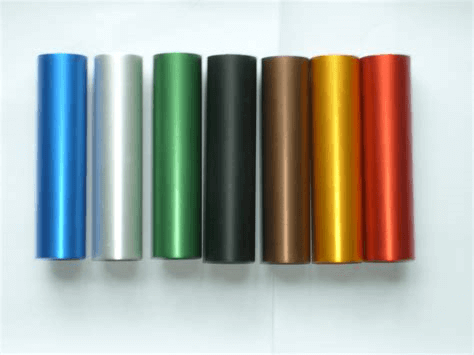

This is the most common process for anodizing aluminum. This option is mostly applied where abrasion resistance and hardness are required. As a result of the process, the sulphuric acid forms a porous film just before sealing. SAA is utilized by adding colored dye, resulting in brilliantly colored surfaces. Popular colors include black, gold, and coyote brown, and urban grey. Parts derived from this process are used in computer and electronic components, mechanical hardware, optical components, and hydraulic valves.

- Hard anodize (hard coat)

This process also involves a sulphuric acid electrolyte. It results in a metal surface that is denser and thicker compared to parts obtained from SAA. It is best for metal components that will be used in extreme wear environments. Extremely high abrasion resistance is required. Hardcoat is also applied where electrical insulation is needed. The parts from hard coating feature improved wear resistance, harder finishes than tool steel, and can be dyed black. Valves, cams, swivel joints, and pistons use hard coat-processed aluminum.

Conclusion

Note, anodizing aluminum results in durable, hard, and abrasion-resistant parts that can be used in consumer goods, electronics, aircraft parts, and sporting gear. It helps metal parts outlast raw metal parts while also providing thermal insulation.