The design of a product determines 75% of the cost of manufacturing it. Many engineers in prototyping companies focus on the aesthetics coupled with the visual appeal of product design without considering the realities of constructing products. It is costly to design the design concept, especially if it is not viable from a business’s angle. Rapid prototyping is the earlier version from which various forms of a product are developed.

How a Prototype Can Make or Break a Product

A prototype provides you with insight into the functionality of the product design while helping you make changes required regarding your products’ specifications.

Several innovators are forming and destroying their prototypes while brainstorming and tweaking them with the hope of developing a revolutionary product in the long run.

An initial product for a pilot test can have drafts of drawings on a paper, also known as a low-fidelity prototype.

High-fidelity prototypes entail the investment of a lot of time and money. Therefore, prototyping is an excellent way of identifying if the solution presented is ideal for the purpose. It could be for a website or hardware.

It could also be for software. Suppose you are a business professional or entrepreneur. In that case, you should begin from the outset by identifying an effective way of identifying the aspects you are working with before developing a product.

What to Do Before Product Development

a. Create Sketches

You may be tempted to use software to sketch things out or start by coding things, mainly if there is time.

Even so, it is highly recommended that you begin by using a pencil and paper prior to investing in a complicated prototyping tool. This will help you in identifying the key aspects that need special attention while doing the prototype on your machines.

When designing a new product from scratch, one of the first steps is often the most challenging, even though it sounds easy for some people. Solidifying the ideas by drawing can be a daunting task.

b. Have Specifications

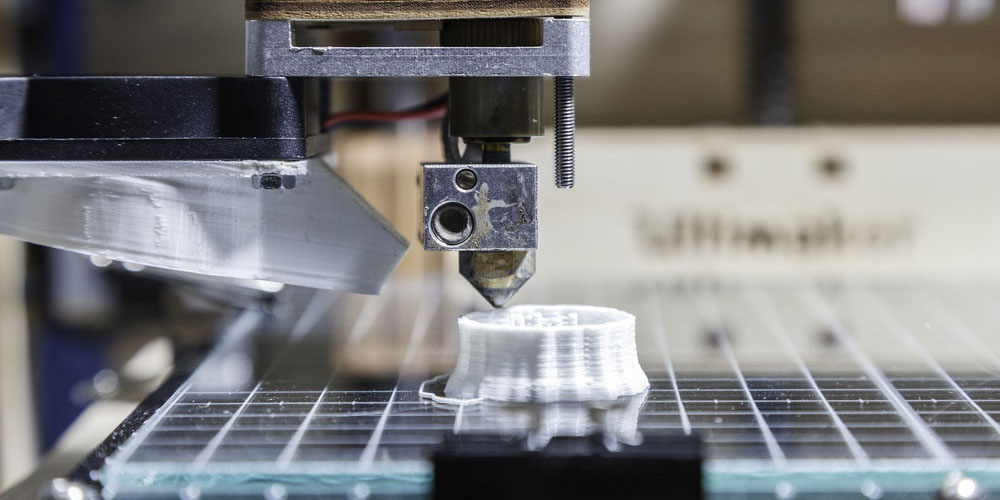

After forming sketches, the next step is having specifications for your product. The 3D printing material and other practical tools like laser cutting coupled with CNC milling have changed prototyping businesses by easing entrepreneurs’ lives.

As an entrepreneur, however, you should design product specifications and then define its existing functionalities before using the tools to offer support.

c. Understand Your Target Audience

Before you create a prototype for your products, you should engage prospective customers to know their interests, coupled with their needs. Introduce the concept to them to help them establish if you are providing a solution to them.

Simultaneously, this should help them determine if what you are creating is a problem for them. At this juncture, the innovator can learn the importance of modifying a product where necessary.

Final Thoughts

An expert in creating prototypes can help your startup bring a new product into the market. By working with professionals, you can easily create a pleasing design solution coupled with a strong focus on reducing the entire manufacturing costs.