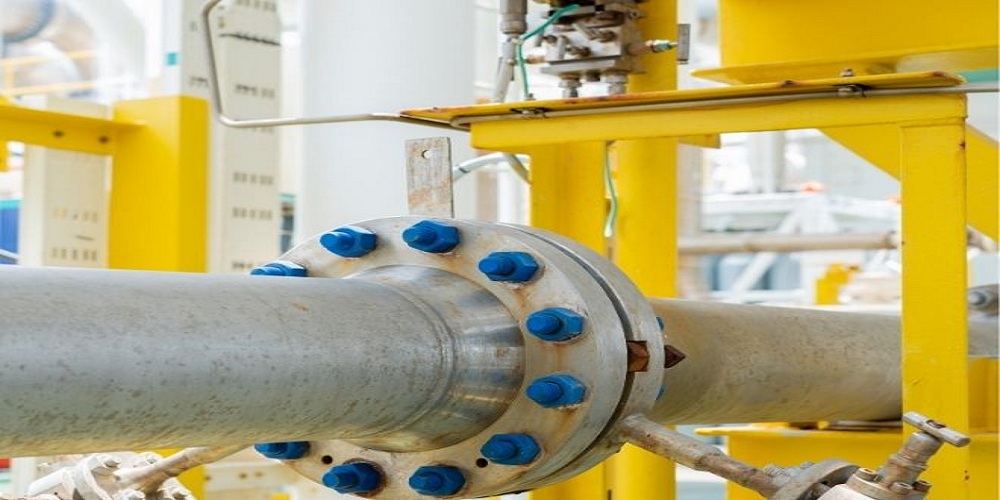

The orifice plate is simply a metal disk/plate. This plate consists of holes in the center. The holes are used to carry the flowing liquid/media pipes to carry them inflow system. These plates, along with venture meters, nozzles, flow conditioners, and fittings, are used in the various metering system to get specific measurements of flow.

The orifice plate is one of the most commonly used items used to measure the flow rate in different industries. The main reason for its popularity is easy availability, affordability, and simple operation.

The market is flooded with different types of orifice plates. All the types differ on the basis of their applications, design, size, material, and price. Here we are going to discuss some main types of orifice plates. Let’s have a quick look!

Types Of Orifice Plates

On the basis of design, orifice plates are classified into four different types such as

There are four basic types of orifices plates based on their designs.

- Quadrant edge

- Concentric

- Eccentric

- Segmental

Here we have a brief detail about all types and their applications.

1. Quadrant Edge Bore Orifice Plate

These plates have a quarter-circle/quadrant to circular inlet shape. This plate is quite thin than other types. The flow pipe is placed in the central hole. The pressure in this plate is generated at a little upstream level. The fluid is forcefully passed through the hole of the plate. The pressure gets reduced after the velocity rises. The radium of the plate can be calculated in d/D ratio (orifice-to-pipe).

Application

The major purpose/ application of this plate is to facilitate the thick fluids that include syrups, crude, & slurries.

2. Concentric Bore Orifice Plate

Concentric plates are the most commonly used because of their simple design and cost-effective solution. The drain hole of this plate is circular. You can install the plate through this hole in the pipeline. You will get accurate measurements from this plate.

These plates are highly recommended for gas, vapors, and pure liquids. Avoid its use for contaminated liquids such as slurry because the solid particles might block the plate hole. It is better to use these plates in upright meter pipes. The manufacturing material of concentric plates is stainless steel, Monel, & nickel.

Application

As above-mentioned detail, these plates are best to measure steam, clean water, & gas flow. Make sure that the Reynolds number of fluid varies from20 000-107 in six inches pipe.

These plates are not suitable for horizontal lines like in multi-phase, which might cause measuring errors, alteration of flow pattern, and blockage of the hole.

3. Eccentric Bore Orifice Plate

Eccentric plates are quite similar to the concentric one except for the central drain hole. This plate is designed for contaminated fluids like slurry. It works well for liquids that have gas in them.

Application

These plates are used to measure the flow rate of liquids that has impurities in them. You can use these plates in petrochemicals, nuclear, steel, paper, and light/ heavy chemical industries where contamination is the problem. It is also used for horizontal meter flow.

4. Segmental Bore Orifice Plate

These plates are segmented rather than being circular. Functionally segmented and eccentric plates are quite similar but quite expensive than eccentric.

Application

These plates are highly recommended for gases and solids that have non-abrasive filths in them. Steel, petrochemical, paper, water conditioning, sewage treatment industries use these plates to measure the flow rate.

Conclusion

If you are looking for a cheap instrument that can be used for precisely measuring the flow rate, then an orifices plate is the best option for you. The best thing is that they come in various designs and sizes. You can select any of the above-mentioned types of the orifice plate as per your requirement.