Making cnc aluminum sounds like a cool idea to anyone until the time for action really comes. Everyone assumes that a CNC machine is there to make the whole process effortless. Of course, machines are being invented to bring about ease in our processes. CNC machines are even more amazing as they ensure that you do not need to oversee the machine production. The CNC machine depends solely on computerized programs to work perfectly. All you need to do is understand these programs, and give the right commands at the appropriate time. The first stop is the computer-aided design segment. In this segment, you are designing what you intend to create with the CNC machine. The design is in a 3-dimensional way. Therefore, you will see it clearly. Hence, you can easily spot mistakes and make appropriate corrections. After achieving the perfect design, you can use the same program to activate the device to commence production.

There is little or no input from you when you are using a CNC machine. However, there is a need to learn how to use a CNC machine the right way. Using a CNC machine is an easy job, but it requires knowledge and a lot of experience. For instance, you need to get a minimal degree to understand some basic processes. But that degree doesn’t mean you know how to operate the machine. That knowledge will come through experience watching and using the CNC machine. Using a CNC machine is a process that needs your attention from start to finish. You want to ensure the machine works automatically. Therefore, you must ensure you are using the right tools and processes. This article is your guide to using a CNC guide from start to finish. Please note that understanding the content of this guide doesn’t make you a qualified CNC operator. You still need experience. Here are some of the processes

Prepare properly

The moment you turn on the CNC machine, the device starts work. If the device starts working in bad condition, it is not a great one for the overall health of the machine. Therefore, before plugging the machine, you may want to check the oil levels and the coolant. Also, check the area the machine is to ensure there is no obstruction that can lead to mistakes and miscalculation.

Plug your machine on

Of course, you need to switch on the machine to use it. The power button is usually behind the left corner of the device.

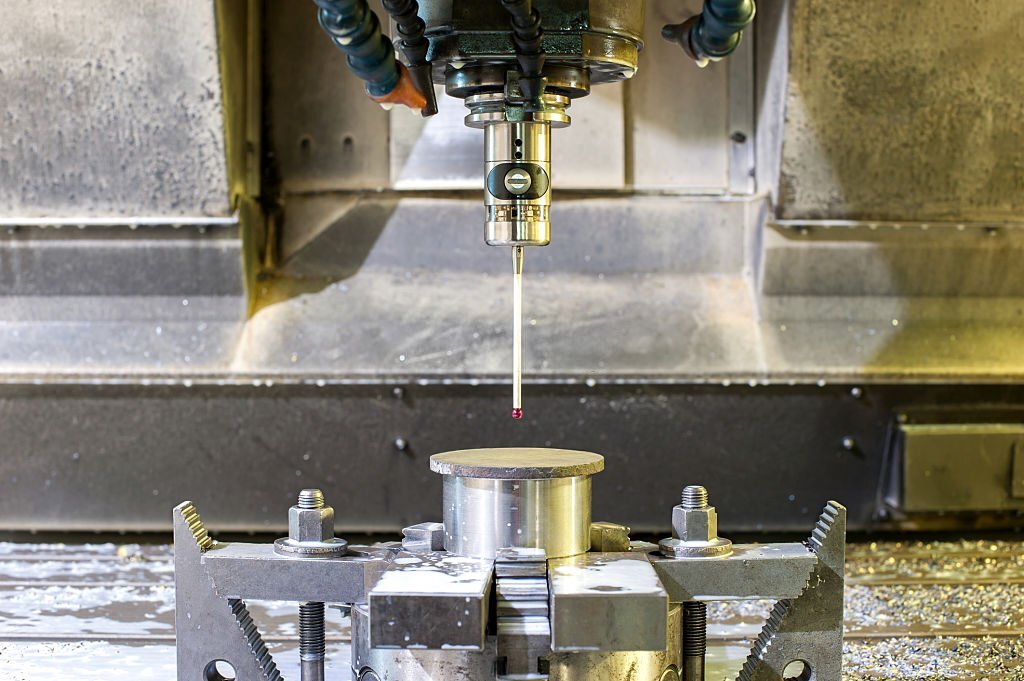

Arrange tools

You need some tools for CNC machining. Each CNC machine program has the necessary tools and arrangements. So arrange the tools accordingly. You can also set your material in the vise.

Set offsets appropriately

The CNC machine program has a specific offset length to set the materials to. Ensure you have the right offset for the materials in the vise and the other parts.

Enter your program and test run

If you have followed the steps from the top accordingly, you have the right arrangement. You can now start your program. Ensure you test run the program on air before running the program on the machine. You may not get it right at the first trial, but do not hesitate to make necessary corrections