Technology improvement is essential in any industry. Such is because it will help in making progress associated with performance and working conditions. In connection to that, the technology in the induction melting furnace field is continually improving and advancing its performance. There are numerous models of melting furnace based on the substance you want to melt. In this article, we will talk about the platinum melting furnace. Here are some of the things you need to know before you decide to invest in high quality and reliable melting furnace.

- How to find the best platinum melting furnace?

Just like in all the growing markets and manufactures, everyone is striving to meet the quality standards at affordable price. It’s the only way one can become a market leader across the globe in a specific field. When it comes to selecting the best platinum melting furnace, make sure you look at various aspects like melting point, smelting platinum ore and also platinum refining procedure.

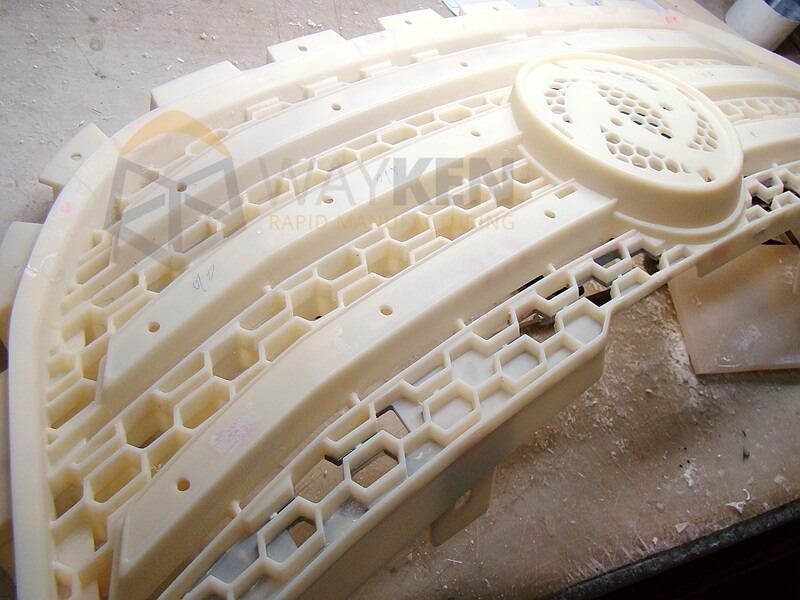

Ensure you consider all these aspects since the quality of your final products will depend on the quality of the melting furnace you select. Additionally, it is essential to pay close attention to the size since platinum melting machine types are available in different sizes. Some melting furnaces are huge and used in mass production, while others are small and medium-sized.

- How easy is it to use a platinum furnace?

When it comes to choosing equipment and new technology, you need to search for the technology that is simple to use. This is something you need to know before you purchase a platinum melting machine. You have to pay close attention to how easy it is to run the equipment. You also need to look for a professional operator who understands how to refine high-quality platinum.

Depending on the size of the platinum melting furnace, you can melt almost 20 kilograms of platinum. Note the process won’t take much time. You need not more than 5 minutes to melt a batch. It’s a fact that soldering the metal rings together can be a hard task. However, using efficient and stable equipment will give you high-quality platinum. The metal melting is done via the process known as platinum purification.

- What are other aspects to look at when selecting a platinum melting furnace?

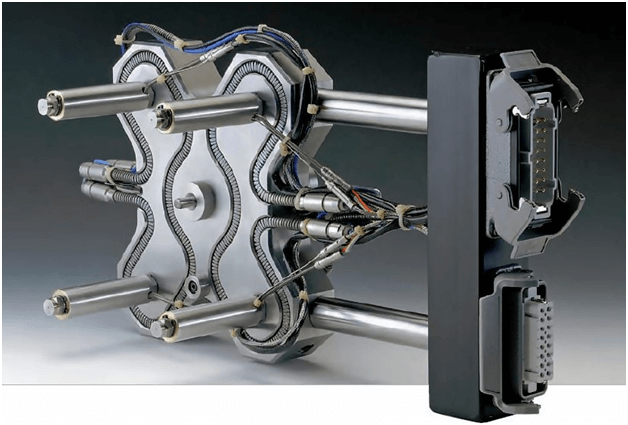

Even though the platinum ore refining procedure is essential, make sure you invest in a reliable melting furnace that is easy to service and maintain. This implies that you must select a platinum melting furnace that comes with digital control and embedded diagnostic features.

Additionally, it is imperative to invest in a melting furnace that has advanced security features, for example, a safety switch. Even though the furnace is safe, accidents do happen. The machine must have countermeasures that will prevent accidents from happening or escalating to fatal states.

Final word

If you are a jewelry lover or just an ordinary individual who needs to melt some metal for whatever purpose, your first step should be finding a reliable melting furnace that fits your needs. This guide will help you get a high-quality product.